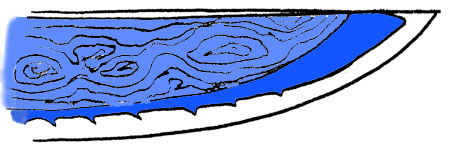

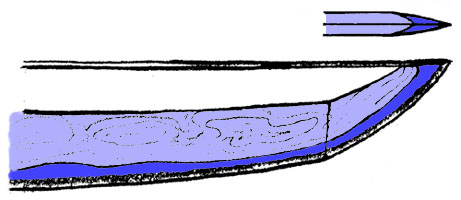

A tachi of "Nobutsugu" (Ko-Aoe, 13c)

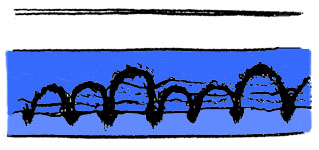

The blade surface is spotted pattern made of two different kind of steels.

One is a little large layer patterned steel. The other is very compact

layer patterned steel. The both are full of fine jinie particles.

The quality of the steels are almost same, only the layer pattern is different.

It can be seen as if the compact layered steel might be under the large

layered steel. But the blade is so healthy that we hesitate to see it core

steel appears.

(=> a broken tachi "Sueyuki" (Ko-Aoe)

A tachi of "Norifusa" (Ichimonji, 13c)

There is a little different layer patterned steel near the tang. It may

be the core steel.

This blade is shortened, and very healthy. So the core steel might appear

from the time it was made.

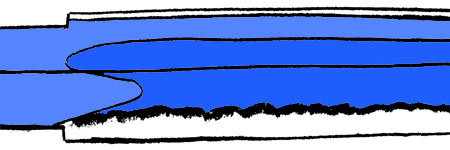

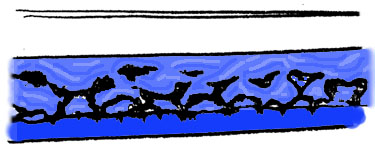

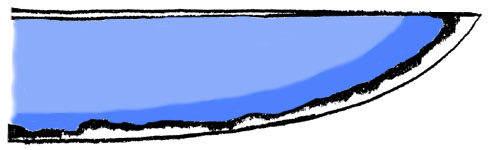

A tanto of "Osafune Kanemitsu" (14c)

It is very weary. Most of blade surface is a core steel that is large wood

grain layer pattern. There is a fine steel around the cutting edge, it

is the outer steel.

In a kantei game, this blade confused people with its Norishige-like steel

appearance. The professor didn't point it as "core steel".

This core steel is lower quality comparing to old masterpieces, but better

than the outer steel of ordinal blades in later period.

A katana of "Tadayoshi" (Hizen, 16-17c)

When we saw the blade at the first time, its surface was bad looking with

its spotted appearance. Rough and soft core steel appears hear and there

in fine steel surface. After a while, we met the blade again after excellent

new polishing.

The blade appearance changed so much. All the steel is

visible small layer pattern. The spotted appearance is masked with it.

A katana of "Kotetsu" (17c)

The blade has a Tekogane, and it runs in the shinogi-ji. But it is difficult

to see the steel in the shinogiji, because it has a mirror finish on the

shinogi-ji.

Tekogane is a word that is used only for Kotetsu blades. It is a little

rough steel that appears near the tang and is different to the steel of

the blade. Sometimes Kotetsu blades have such appearance. They never call

it "Shingane", but it may be core steel in fact.

(His blades have very compact layer pattern, so we are not sure if his

blades could be made by Hon-Sam'mai with the same quality between cutting

edge steel and outer steel.)

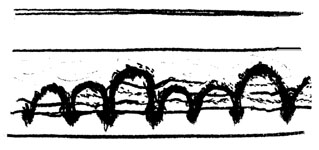

Generally, in Kobuse/Makuri constructions, core steel can appear near the

tang, sometimes in the shinogi-ji or blade surface.

On good blades, the core steel is also well forged, so it is a little difficult

to distinguish it. Especially, good blades before 13th century have very

fine core steel.

From 14th century, the core steel may become rougher slowly.

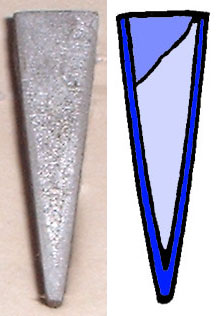

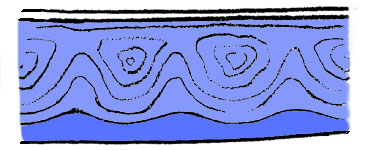

2) Blades that can be seen as the three layered style construction. (Sam'mai, Hon-Sam'mai, Shiho-zume or so)

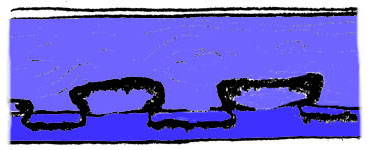

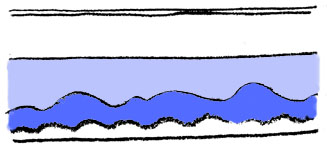

A tanto of "Hasebe Kunishige" (14c)

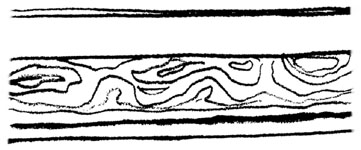

It is a very thin Hira-zukuri blade. The cutting edge steel (or core steel)

is compact layered fine steel. The outer steel is rough quality and large

layered. So the hamon has some appearances that are effected with the large

layer pattern. But the large layer never comes to the very cutting edge.

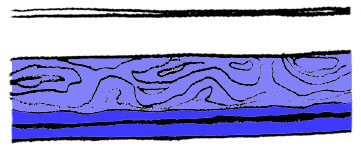

A wakizashi O-suriage Mumei (Ko-Uda, 14c)

The cutting edge steel is forged as compact layer. The outer steel is so

rough as the steel has hard part and mild part along with its large layer

pattern. So the hamon makes active appearances with running rough nie (large

particles). That may be attractive for eyes.

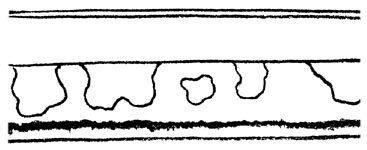

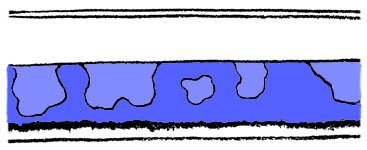

A tanto of "Gassan" (16c)

The layer pattern is Ayasugi-hada, of course. The hamon is Notare (wavy)

pattern along the layer pattern. The hamon doesn't have clear temper line,

but the hardened area is full of nie particles. Probably the hamon-like

pattern is a border of the two steels between outer steel and cutting edge

steel (core steel) .

A katana of "Kiyomaro" (19c)

This blade has similar construction of the Ko-Uda blade what we have introduced

above.

But the unique point of this blade is that the cutting edge steel is softer

than the outer steel. The outer steel is designed to purpose attractive

appearances for eye. The cutting edge steel is ordinal quality in Shin-shinto

blades, though the temper line is how bright.

A katana of "Rekko" (19c)

The cutting edge steel (or core steel) is compact layered fine steel. The

outer steel is mixed steel (hard steel and soft steel) as pattern welding.

The outer steel has a designed layer pattern and is soft in average.

The straight patterned hamon is designed among the cutting edge steel.

So the brightness of the temper line honestly suggests its cutting quality.

In the three-layer construction style, It is not often to find dirty core

steel in spotted pattern.

In some case of Sam'mai, the outer steel is similar quality to the core

steel of Kobuse construction, and a hard steel makes the core and the cutting

edge.

In other hand, there is a unique method that a soft core steel makes a

cutting edge combined with hard outer steel. Such an opposite style may

became popular from Shin-shinto period, as art sword. We can see such blades

in modern products sometimes. (=> Tanto,

Shin-shinto, Mumei)

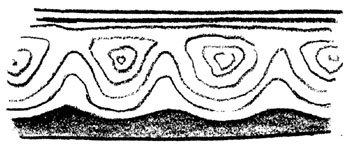

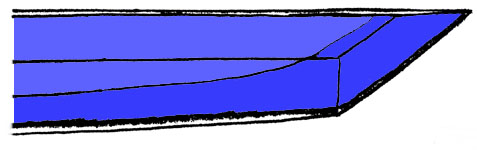

3) Blades that can be seen as the two blocks style construction. (Hyoshigi)

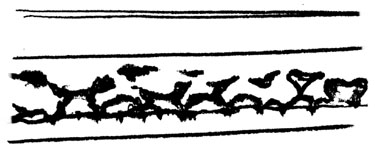

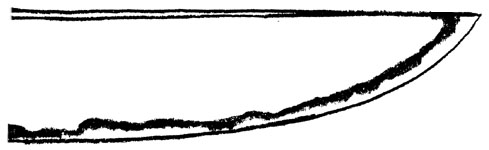

A tachi Mumei (Yamato, 12c)

Very old Tachi blade, may be from 12th century. The hamon is Hoso-suguha

pattern made of konie (small particles).

At the middle of the cutting surface, a border of the steel runs along

the blade length. It may be made of the two blocks construction.

The cutting edge steel is a wood grain layer pattern, and the back steel

is a flowing layer pattern. The back steel seems a little softer than the

cutting edge steel.

A tachi "Amakuni" (13c )

A very old Tachi blade, may be from 13th century or older. The hamon is

Hoso-suguha pattern. The border of the steels runs along the hamon.

The cutting edge steel is very compact layered fine steel as the fine hamon

appears.

The back (or body) steel is fine. It has very large wood grain layer pattern,

but not rough. The pattern can be seen as an appearance of jinie effect.

A tachi mumei (Taema, 14c)

The layer pattern is straight in the shinogi-ji and in the hamon area,

a wood grain on the middle part of the width.

It seems like there are two different steels as their layer pattern, one

is for the shinogi-ji and the other is for the cutting surface. But their

quality looks almost the same.

In the general, it is rare to find core steel in Yamato tradition blades.

4) Very weary blades and some interesting blades for study.

A tanto Mumei (12c-13c)

A very old tanto blade. It is so weary that the thickness and the hamon

has become very thin.

The hamon is Hoso-suguha made of mild konie. The steel is fine, full of

small jinie, and the layer is very compact.

A professor suggests it Muku, because it appears no core steel in such

a weary condition. But we can consider if it would be all core steel by

all the outer steel has ground off.

A tachi "Nagamitsu" (Osafune, 13c)

It is one of the blades that found in a grave of Shogun. It was covered

with very deep rust and then it was polished up.

The steel is a large wood grain layer pattern and some rough layer appears.

The hamon is Gunome made of mild konie, and the hamon line is not very

sharp, a little spreading.

That seems a little softer comparing to his usual blades. Probably the

surface is almost core steel.

A tanto "Takagi Sadamune" (14c)

It had been very damaged with rust while sleeping in shelter during WWII.

Then it got new polishing and recalled its beauty. But one pin hole is

left that rusting through the blade surfaces. It is so weary.

The hamon is a narrow Notare and Gunome pattern made of nie.

The steel is almost fine with very compact layer, only the area near the

hamon is a wood grain layer pattern. But the border of the steel appearances

is not clear for eye.

We can consider if the fine steel is the core steel and the wood grained

steel is outer steel in Kobuse conctruction or so. In other possibilities,

the difference of the steels comes from the hardening effect.

A tachi Mumei "Tametsugu" (or Norishige, 14c)

The steel is mixed, making large wood grain and burl layer pattern. The

hamon is an active pattern with nie that runs along the layer pattern.

The appearance that made with the layer pattern and the nie particles is

attractive for eye, but it can't make a clear hardened area because the

steel is not so sensitive.

This blade may be Muku, but the steel quality is not very hard on the whole.

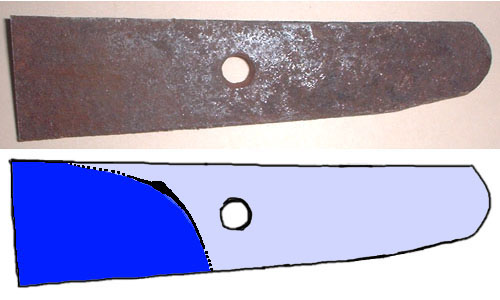

A katana "Osafune Tadamitsu" (15-16c)

An ordinary quality blade of his work with Suguha hamon. It is not very

weary, but the core steel appears here and there. Sometimes we see such

blades that has thin outer steel in that period.

The outer steel is a little rough wood grained, and the core steel is fine

with compact layer and fine jinie. The outer steel looks dirty and the

core steel looks beautiful. So the owner wished all the outer steel could

be ground off.

A sample of fine core from 16th century

A katana "Osafune Shigemitsu" (fake, 19c)

This is a fake blade in 19th century. Sometimes we find such fake blades

made in 19th century. It is famous as being called "Kuwana" blades.

This blade may be constructed with Kobuse or Makuri method. The outer steel

covers the area around the hamon, and the dim colored core steel appears

as irregular pattern in the blade surface. The method is purposed to trick

beginners' eye making utsuri-like appearance.

A tanto "Naohiro" (21c) (=> tanto

"Naohiro" Kata-kiriha-zukuri)

The smith explained the steel construction of this blade.

This Kata-kiriha-zukuri blade is made by the method putting a hard steel

on one side (Hari-hagane). The body steel is made of many small pieces

of remnants that cut off from blade/tsuba making. He gathered the small

pieces and welded them into one block, then folded 5 times.

The polisher who polished this blade said that the hamon on the obverse

side is hard, but the reverse side is not so.

On the reverse side, the layer pattern is slowly flowing. On the obverse

side, near the back is so, and around the hamon area is compact layer.

The appearance may suggest the difference of the steels. But the steel

has other appearances that come from the hardening effect, so it is not

so simple to study the blade surface. Though by careful studying, it is

difficult to find a border of the steels.

We tried not to be able to identify each of the blades. We are afraid if

the owners would not want to see core steel in their blades, because the

word "Shingane" still sounds bad.

A core steel appearing never determine the quality of the blade. The quality

of the steels is important.