We have had more requests of sword made from meteorites. And we have got more meteorites. Then, we are making more swords with them. They are going to be mixed with tamahagane.

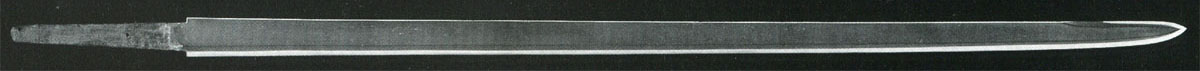

We are planning to make long blades like this shape. Blade length may be around 70cm.

The cost will be around 800,000.yen what includes full polishing and mounted within shirasaya.

We are going to make two or three blades. One is reserved by Mr. F.C.