Do not confuse the real hamon with the white made-up pattern by the modern style polishing. We call this white pattern "HADORI". To find the real hamon in this style polishing, a good lighting is necessary. (=> polishing)

-For beginners-

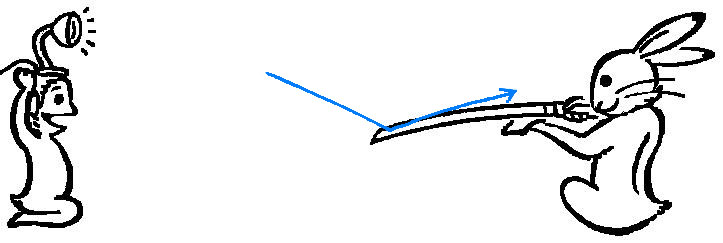

Please let the light reflect on the cutting surface of the blade.

You shouldn't settle the blade close to your eyes. Relax your arms and keep the blade at a distance from your eyes.

When you get a good angle between the blade surface and the light, the real hamon becomes very visible as a white line. A dark cartain as background of the light can make it easier to see hamon.

This way of seeing hamon is necessary to find a real hamon in the modern style polishing. It is also very important to break a fake hamon. (=> fake hamon)

Utsuri (shadow of hamon), also can bee seen by this way.

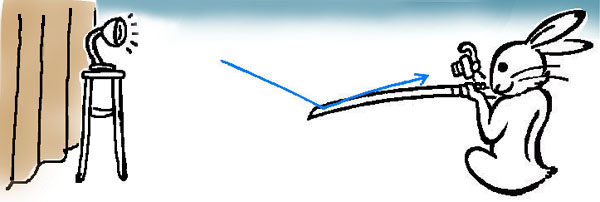

Usually we use a bulb. A normal size white bulb is very good.

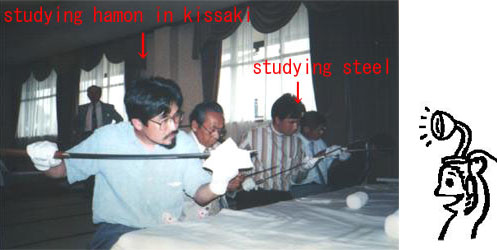

This photo emphasizes the light too much by the camera effect.

This photo emphasizes the light too much by the camera effect.This kind of light stand is useful too.

Sometimes the natural light through the bright window also is useful. When the blade is polished by the classical style, such a lighting is very good to study the blade quality.

Please be familiar to find a good lighting to see the hamon clearly.

A scene at a Kantei game

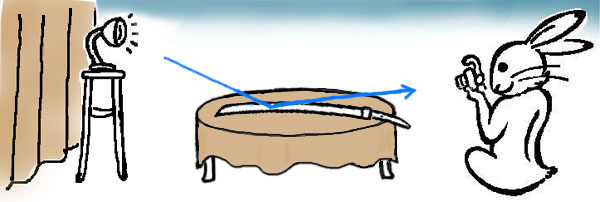

We try to take pictures of hamon by camera.

Settle a light stand before a dark curtain, and down the ceiling light not to mirror furniture into the blade. Handle the blade with one hand, or put on table with dark cloth. Find a correct angle that the hamon comes up clearly. Then take a picture without flashing.

The pictures taken by this system can bring us similar images as we actually see the hamon with blade in hand, even though they are not as sensitive as we have in eye.

Lightning pattern in the Choji pattern hamon.

Sweeping pattern in the Gunome pattern hamon.

HAMON particles, NIE and NIOI

A hamon area, hardened area of the blade, is a mass of the hardened steel crystals. A hamon line is made of small particles of hardened steel. (Please see note at bottom.) The hamon line can be seen as a mass of bright white particles.

The particles are classified with different names by their sizes. They are roughly called NIE and NIOI.

The smallest particles are NIOI.

It is hard to recognize each particles on the hamon. The hamon pattern that made of NIOI looks like a narrow white line.

The visible particles are called NIE. It can be seen as a construction of many grits. NIE is classified into three sizes again.

1) Small particles are KONIE. It means a small nie.

2) Large particles are NIE.

3) Rough particles are ARANIE. It means a rough nie.

So the particles are classified into 4 degrees by their sizes.

nioi (smallest) => konie (small) => nie (large) => aranie (rough)

But the classification is not exactly. They are seen as combined form on the hamon.

In roughly speaking, the sizes means a temperature of the heat treatment. The steel crystals become larger by heating. So the hamon line made of NIOI is lower than the hamon line made of NIE in the work of heat temperature. Therefore, NIOI hamon on tight steel tends to be sharp edge, and NIE hamon on rough steel tends to be tough edge.

But actual blades are not so simple. Seeing the brightness of particles is very important to appreciate blades.

We have been looking for good words that translate "NIE/NIOI".

For example, nioi = smallest particles, konie = small particles, nie = large particles.

But I have not found proper words yet.

Studying NIE/NIOI is very important to appreciate Japanese blades. We will use the Japanese word "nie and nioi" for a while until we find good translation.

NIOI

It is rare a hamon what made of only nioi. In most of cases, a hamon what looks made of only nioi, can include also some amount of konie.

This white pattern is not hamon. It is "Hadori" what is the cosmetics created by the polisher.

Real hamon exists under the strong hadori.

Small particles (KONIE )

Large particles (NIE)

NIE with dense nioi bed.

Rough particles (ARANIE)

Note; (by metallurgical words)

A hamon area is a mass of the hardened steel crystal. The structure is called "Martensite".

The hamon particles, NIE/NIOI, can be described as "discrete martensite".

The hardening work on hard steel can make several phases of steel structure. Martensite is very hard one. And there are some other milder structures. Each of phases come by tempering effect.

The hamon line is a border of hardening effects between the hardest structure (martensite) and the milder structure. The particles appear as discrete martensite in the milder steel structure. There are various sizes of discrete martensite. It looks like rising dots in mild base by polishing. Traditional polishing work brings them as white bright particles. The smallest is called Nioi that is not visible as particles by eye, and some larger are called Nie that is visible as particles.

The phases of hardening effect is not so simple in the actual work on blades. Good blades show us many different phases in sensitive steel. (=> Utsuri = shadow of hamon)